Violin Maker London

Making violins at the Ruschil workshop, London

We look at some of the steps and processes involved in making a fine violin in the workshop. Performed by a trained luthier, with experience handed down through the generations, we see in detail the skill that it takes to make a violin.

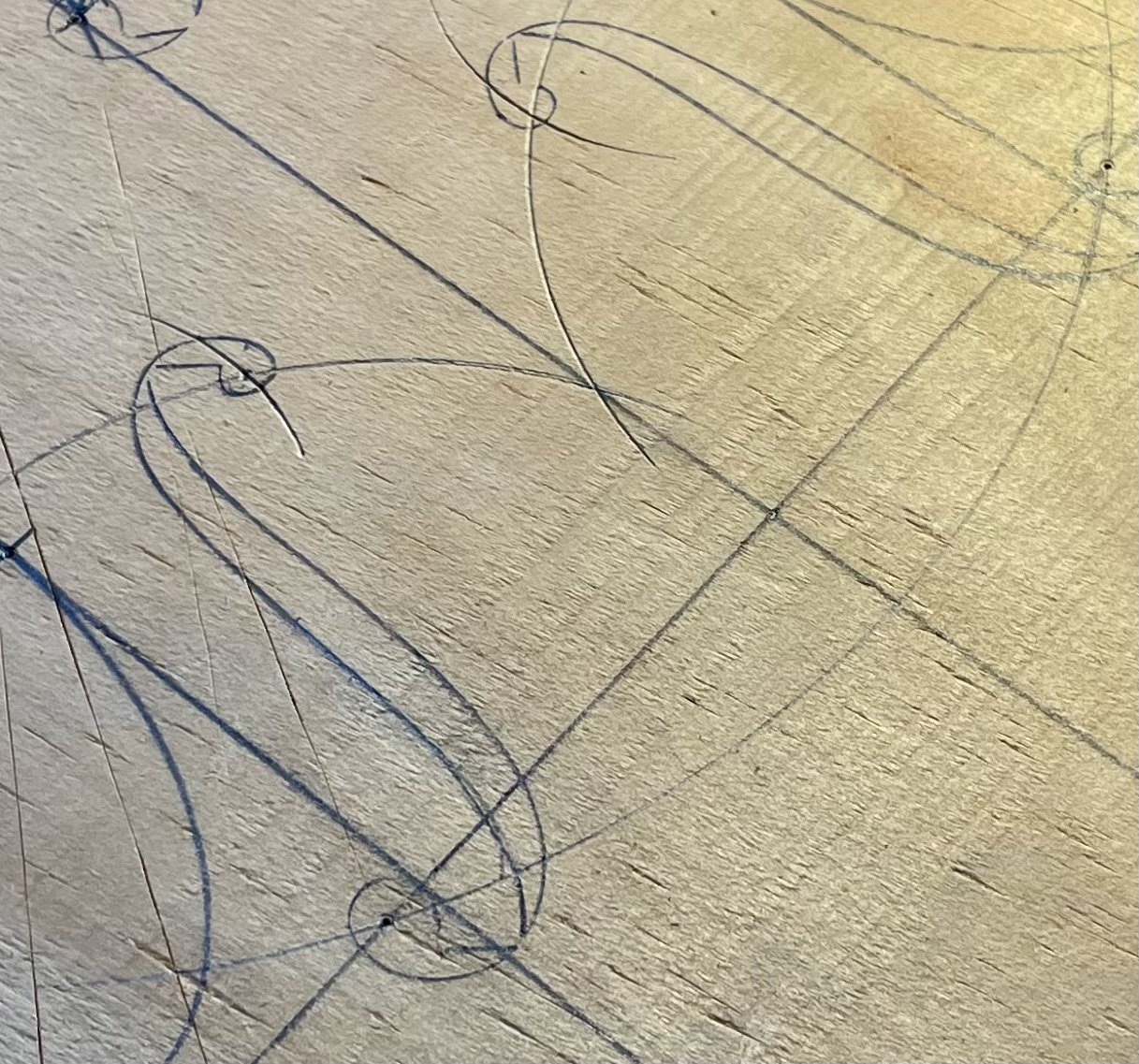

Violin Scroll Carving

The head of the violin, or “la testa” in Italian, is handcarved to be both functional and beautiful. Carefully planned and drawn out onto the wood, using classical geometry and the old Cremonese method, the scroll takes shape to become part of the violin. Years of in-depth study of old Italian instruments by the luthier creates more and more experience, to perfect and refine our violin scrolls.

Above: Three violin scrolls being handcarved by a master violin maker in the Ruschil & Bailly workshop

A Master Violin Maker Carving a Scroll

Using precision saw cuts, gouges, chisels and scrapers, every violin handmade in the workshop is created by a master luthier. Below we see the various shapes of the scroll taking form, including the volute, chamfer, pegbox, chin and neck.

Get More Information & Play Our Violins

To learn more, ask a question or play our violins please contact us using the button below.

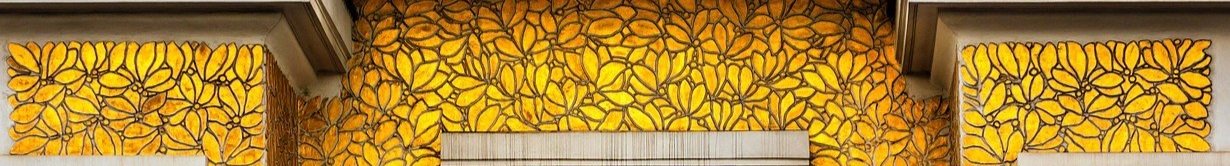

Violin Purfling

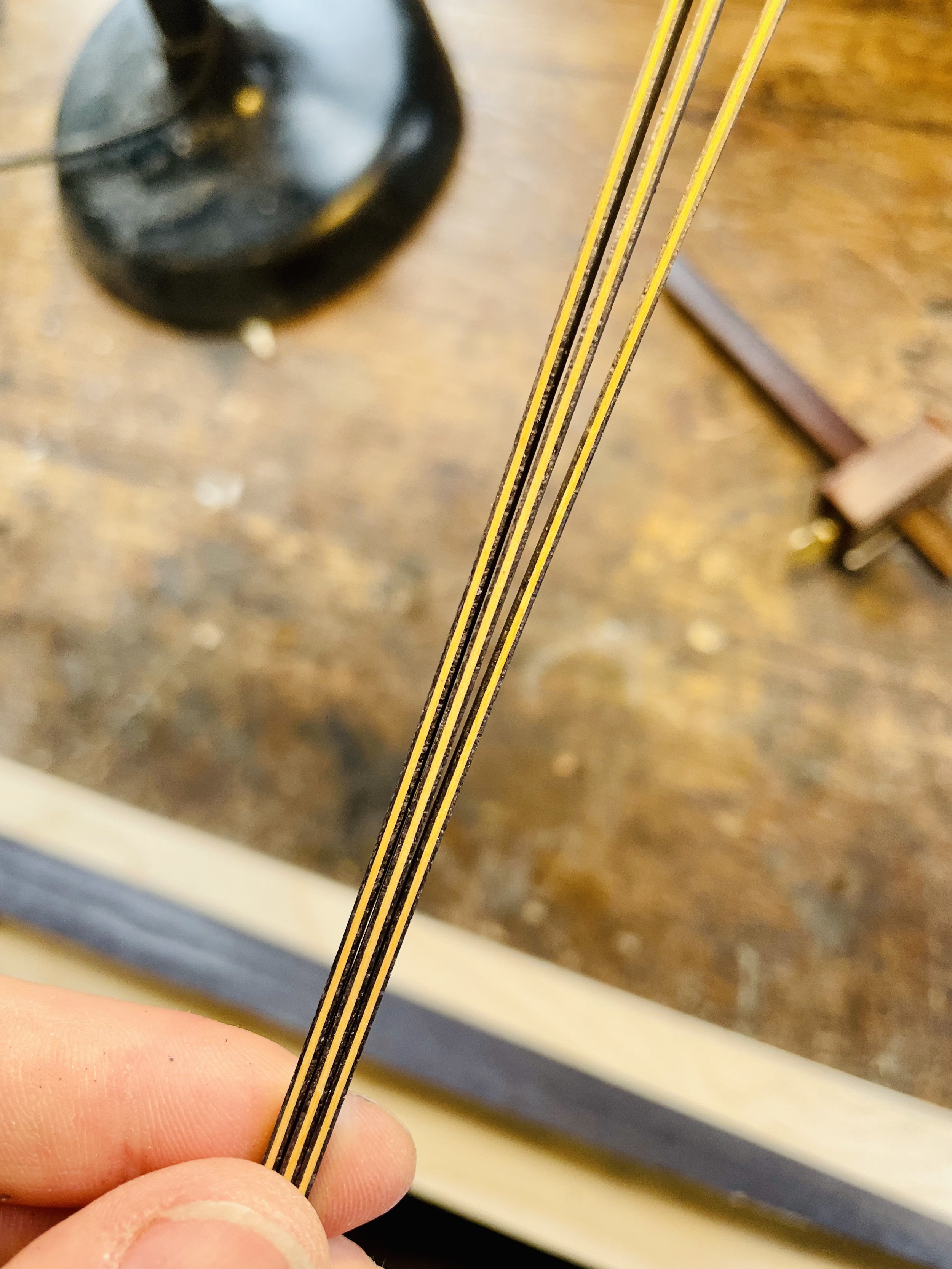

To strengthen and decorate violins, a violin maker will make purfling. Sheets of wood veneer are carefully glued together and cut into strips to create a binding that will be inlaid around the perimeter of the instrument. Various woods are used as can be seen in the photo here, including pearwood, ebony, maple, rosewood, camphor and pernambuco.

Below: Veneer sheets being glued together to create purfling and inlaid into a violin by a violin maker.

Below Left: Three strips of wooden veneer that make violin purfling, in this case stained pearwood & bird’s eye maple.

Below Right: Ruschil & Bailly workshop violin, “The Pearl” created with stained pearwood & boxwood purfling, a traditional English design.

Violin F hole Placement and Carving

Using classical geometry and the unique outline of each violin, bespoke f holes, or soundholes, are carved by the violin maker. They will have a big influence on the sound quality of the instrument, as well as adding style and character. The best violin maker will be able to carve f holes that bring all the elements of sound and style together.

Above: The violin maker uses classical geometry to place the f holes on a Ruschil violin.

Violin Making Knives

To ensure that a violin is made or set up to the highest standard, violin makers make knives for different jobs. Below is a selection of some of the bespoke, handmade knives in the Ruschil workshop, London.

Bespoke violin maker knives handmade in London from Japanese steel, desert ironwood, purple heartwood & pyinma burl

Violin Varnishing

Using a traditional oil varnish, handmade in the Ruschil workshop, London, the master violin maker enhances the beauty and sound of the wood.

Applying it in fine layers over the course of weeks, the violin’s sound is perfected whilst protecting it for centuries to come.

Get More Information & Play Our Violins

To learn more, ask a question or play our violins please contact us using the button below.